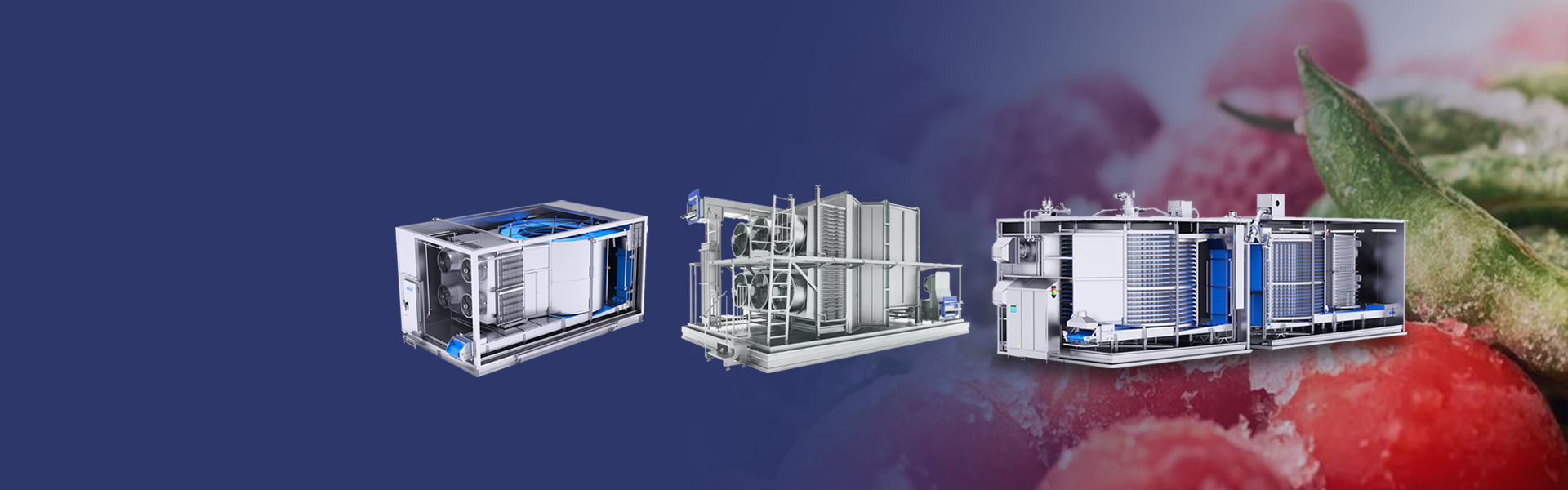

Product Introduction:The vacuum pre cooling machine for cooked food is a cooling equipment for high-temperature cooked food p

Product Introduction:

The vacuum pre cooling machine for cooked food is a cooling equipment for high-temperature cooked food preservation and packaging front-end. It is an indispensable food pre cooling mechanical equipment for solving the problem of high-temperature cooked food preservation and packaging in developed countries such as Europe and America.

Implementation principle:

The principle of vacuum precooler is that at a standard atmospheric pressure, the boiling point of water is 100 ℃, and the heat of evaporation is 2256.69KJ/Kg; When the pressure drops to 613 Pa, the boiling point of water is 0 ℃, and the heat of evaporation is 2499.52 kJ/Kg. As the pressure decreases, the boiling point temperature of water also decreases, and the heat consumed per unit mass of water evaporated actually increases. The principle of vacuum cooling technology is to place high-temperature objects such as fruits, vegetables, and cooked foods that are being cooled in a vacuum cooling chamber, and use a vacuum pump to extract air to create a low-pressure environment, allowing the moisture inside the product to evaporate; Due to the heat absorption accompanying the evaporation process, the temperature of the evaporated material itself decreases. This process is divided into two stages: firstly, the pressure inside the vacuum chamber is reduced to the saturation pressure corresponding to the initial temperature of the product. At the saturation pressure, the flash point appears. In this stage, the evaporation rate is slow and the cooling effect is not obvious. Then, the pressure continues to decrease and evaporation begins; Secondly, as the evaporation process progresses, the temperature of the evaporated object begins to decrease until a predetermined temperature is reached. The cooling rate of a vacuum pre cooler depends on the temperature difference of the cooled food, and the smaller the temperature difference, the faster its cooling rate.

Product features and advantages:

1. Fully automatic control system, easy to operate;

Advanced fully automatic control system, technology from Tsinghua University, the entire cooling process is controlled by computer PLC. Users only need to press the "start" button on the touch screen to make your operation simpler. All cooling data, temperature and other parameters can be output, printed and saved.

2. Cooling time;

The product can be cooled from 90 ℃ to 18 ℃ at room temperature in just 15 minutes.

3. The cooling temperature is uniform, the taste remains unchanged, and bacterial growth is avoided;

The cooling temperature of the product depends on the vacuum degree inside the vacuum cooling box, and the pressure value of the vacuum degree inside the vacuum cooling box is equal, so the temperature of the cooled product is uniform inside and outside, without internal cooling or external heating, the taste remains unchanged, and bacterial growth is avoided.

4. Avoiding secondary pollution of food by the environment;

The cooling process is carried out in a sealed vacuum state, avoiding the problem of product deterioration, so there is no bacterial infection.

5. Improve the quality of cooked food products;

The product has a bacterial growth period from 30 ℃ to 60 ℃, but due to the short cooling time of the vacuum cooler, the shelf life of the product is extended, ensuring its freshness. Since there is no bacterial growth, there is no need to add preservatives, making the product a "green food".

6. Improve the taste of cooked food products;

Due to the principle of vacuum impregnation, the concentrated soup and high-quality ingredients caused by external dehydration can be evenly introduced into the interior of the product, thus improving the taste of the product.

7. Small footprint, safe and hygienic;

Small footprint, can be directly installed on the product site, does not produce any pollution during operation, is clean and hygienic, and does not require maintenance!

8. Equipment material specifications and long service life;

The equipment is designed to have a service life of 30 years, and the body is entirely welded seamlessly. The main configurations are imported.

Home

Home

Product

Product

News

News

Contact

Contact