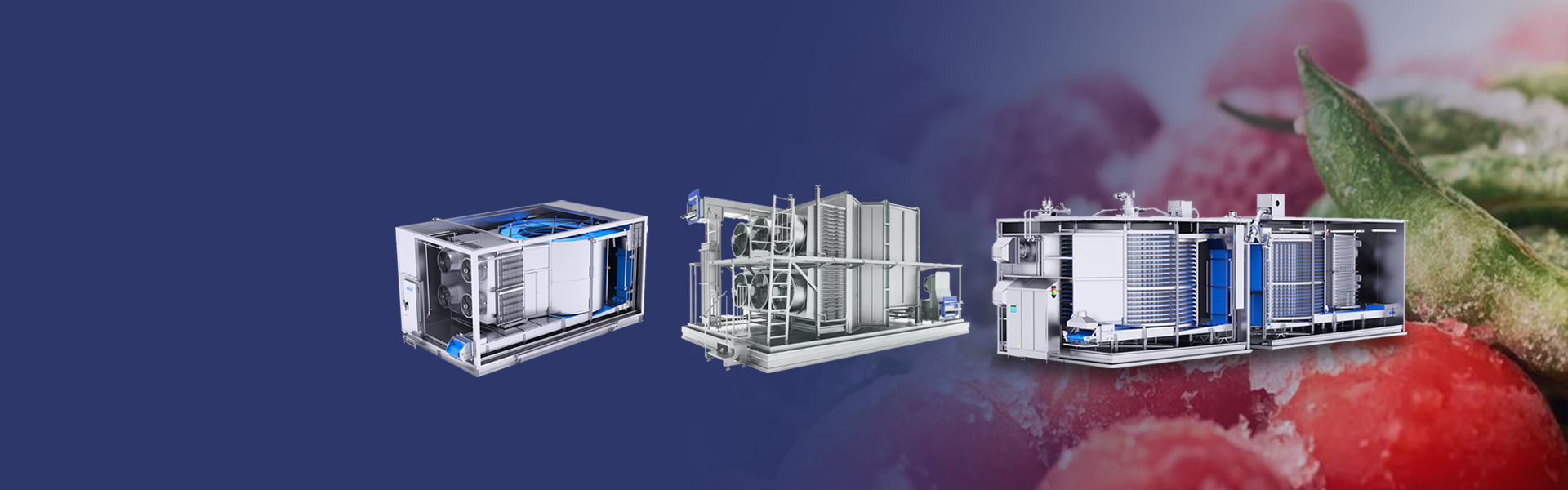

The jet tunnel quick freezer is specially designed for the low-temperature air flow and air duct circulating in the warehouse

The jet tunnel quick freezer is specially designed for the low-temperature air flow and air duct circulating in the warehouse. When the food passes through the quick freezer with the conveyor belt, the upper and lower surfaces of the food are blown opposite by the uniform Jet stream, and the surface temperature of the food drops rapidly, which can complete the quick freezing process of the food in a short time.

The impact tunnel is particularly suitable for rapid freezing of granular, small, and flat foods, such as shrimp products, fish fillets, hamburger patties, and other thin slice foods.

Simple structure, convenient operation, and long service life

The warehouse board adopts double-sided stainless steel polyurethane sandwich insulation board, with good insulation performance;

The internal components are made of SUS304 stainless steel material, which is easy to clean;

Adopting stainless steel mesh belt, the surface is flat and easy to clean

Using water to flush frost to ensure cleanliness and hygiene

The frequency converter control achieves stepless speed regulation, and the freezing time of frozen products is adjustable, which can be applied to the processing of various frozen products;

Quick freezing does not produce large ice crystals, and tries to maintain the quality of the food as much as possible. After thawing, it remains fresh as before, with fast freezing speed and low dry consumption of the frozen product.

※ The surface of food quickly hardens and crusts, locking in internal moisture, reducing the dry consumption of frozen products to a very low level;

The short freezing time not only maintains the freshness of the food, but also provides good freezing efficiency;

※ Frozen products have high quality, better color than traditional spiral, flat mesh, and other frozen products, and have small temperature errors in the middle of the food;

Shortening the freezing time can reduce the overall device volume and make the equipment space requirements smaller;

※ The freezing speed is fast, increasing by 40% compared to traditional spiral and flat nets;

Home

Home

Product

Product

News

News

Contact

Contact